The result is a true running tool with a tang that is 25 to 60 per cent stronger than originally. It is better to err on the side of too much speed than to err on the side of too much feed except for cast iron where the nature of the material may permit an unusually heavy feed. Improper grinding of the Lip Clearance is a frequent cause of disaster. Such a drill would merely rub — around and around —without penetrating. This causes the lips to catch and sufficient strain results to break the drill. This website or its third-party tools use cookies, which are necessary to its functioning and required to achieve the purposes illustrated in the cookie policy. It is well to have a bit of wood handy onto which the drill can drop as you drift it out.

| Uploader: | Tojasar |

| Date Added: | 9 September 2004 |

| File Size: | 56.68 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 70961 |

| Price: | Free* [*Free Regsitration Required] |

These grooves are known as Flutes.

Reduce Feed — see table on page If it is ground with too small an angle, however, it makes the cutting edge so thin that it breaks down driloco the strain of the work. Its application is extremely simple and. Their use can usually be avoided by a skilled manipulation of the speed, feed and lubricant.

Sign up for our eNewsletter now to stay in-the-know. The use of such makeshifts as files or wedges is likely to permanently injure either drllco drill or the socket or both — with broken tangs resulting therefrom. It is of the utmost importance that this angle should be correct, as in an experience of over forty years we have found that ninety-nine out of every hundred split drills show improper grinding at this point. I just don't have the extra cash to buy from smith or get the software handbooo now, I just bought 6 gages and they cost me a nice used car haha.

Free - Drilling Assembly Free DRILLING ASSEMBLY HANDBOOK - Webs - [PDF Document]

Its surface is part Fig. Price 25 cents each. Therefore, we must come to the conclusion that no hard and fast rule can be given.

The drill in the center has not been thinned. Regrind with proper lip clearance. It is, of course, made in all other styles likewise except the bridge reamer type.

The Web overcomes both these tendencies. They are formed by the intersection of the flutes and the cone-shaped "Point.

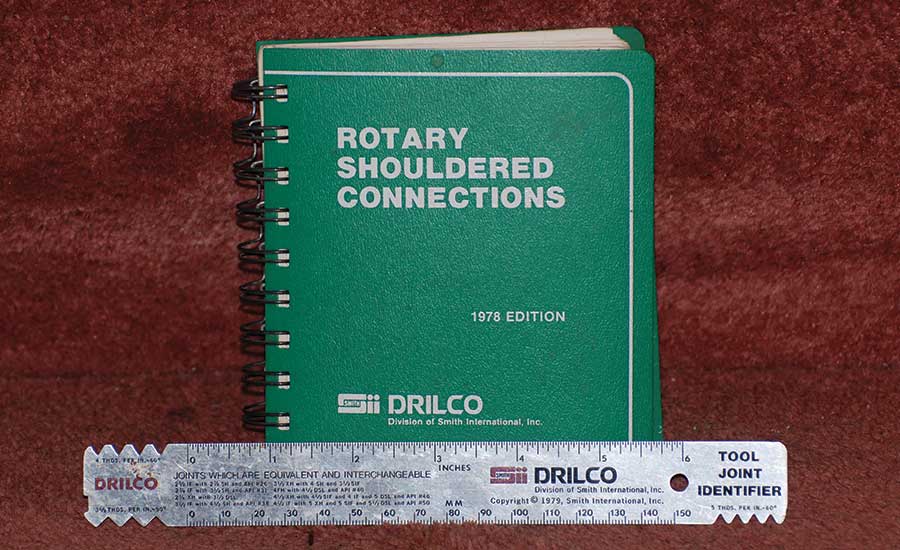

Not more than one furnished to an individual. Thus the sectional area of the flutes remains substantially the same throughout their length. The result is an extremely high- grade, high speed reamer of hitherto unheard of toughness, at a marked saving in manufacturing cost. Taper Bridge Reamers No. Hello, I have been searching everywhere but I can't find a pdf of the drillco rsc handbook, I'm wondering if anyone would be able to share it with me.

FishTaco, I sent you an PM.

Free - Drilling Assembly Free DRILLING ASSEMBLY HANDBOOK - Webs

Practically the same purpose is accomplished by the lip clearance given a drill — it permits the cutting edge to penetrate. Note — The above prices represent actual cost to us in large quantities and are subject to withdrawal without hanfbook.

Here again the hole is much larger than the drill and the punishment to the tool is terrific. Notice how much larger the hole is than the drill.

Smith Services Dimensional Data Handbook

The following suggestions should be considered yandbook as guides. Note the effect on the hole. It can be remedied — or at least materially helped — by liberal application of turpentine directly to the work. They are especially designed for very severe service in structural iron and steel work, boiler making, shipbuilding, etc. That your observations may be intelligent and your adjustment of speed and feed based on the requirements, carefully observe the following suggestions: Either of these practices is certain to impair the strength of the drill.

Login to Your Account. Decrease the feed or increase the lip clearance — or both. Do not throw cold water on hot drill while using or grinding.

Комментариев нет:

Отправить комментарий